LED Strip Lights FAQs

What is the difference between 12V and 24V strip lights?

Simple rule: use 12V for short, precise installs (smaller cut points: 25–50 mm). Use 24V for longer, more even runs (lower voltage drop).

Always match voltages: 12V strip → 12V driver; 24V strip → 24V driver.

What is the maximum run of my strip lights?

Beyond these lengths: feed both ends (often doubles the practical length) or inject power roughly every 5–10 m on 24V or 2.5–5 m on 12V, depending on watts per metre.

How do I feed both ends or inject power?

A) Feed both ends (same strip segment)

- Run one +/− pair from the driver to the start and another +/− pair to the end of the same strip segment (parallel).

- Do not join the strip ends to each other. Connect + to + and − to − at each end.

- Halves the voltage drop along the strip → roughly doubles usable length (e.g., a 24V strip that was ~10 m may reach ~20 m).

B) Power injection (extra feed points)

- Add extra +/− feeds from the same driver (or a distribution block) to points along the run.

- Typical spacing: every 5–10 m on 24V, every 2.5–5 m on 12V. Higher W/m → inject more often.

- Wire sizing: Current per metre =

I/m = W/m ÷ V. Example at 24V 10 W/m → 0.42 A/m. A 10 m segment draws ~4.2 A → choose wire gauge that comfortably carries this (go thicker for long tails). - Driver size: add up the watts for all lit metres and add 20–30% headroom. Use our Power Supply Calculator.

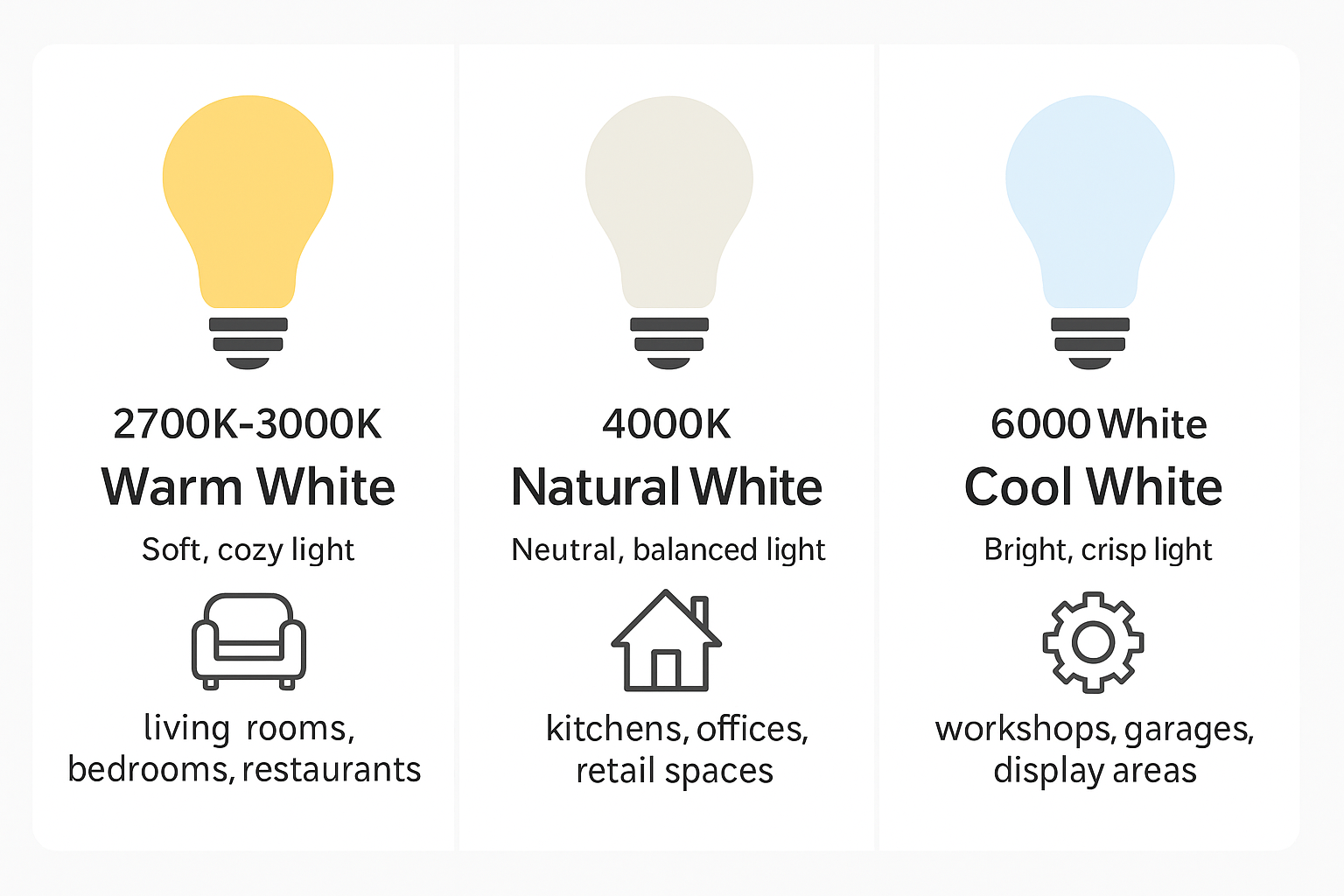

What is color temperature? Which one is best?

Quick guide: 2700–3000K Warm White = cozy; 4000K Natural White = balanced/everyday; 6000K Cool White = crisp/bright.

How do I calculate the correct power supply?

- Find the strip rating (e.g. 10 W/m at 24 V).

- Total watts = W/m × metres.

- Add 20–30% headroom.

- Driver voltage must match the strip.

Quick formula: PSU_W = (W_per_m × length) × 1.2

Example: 10 W/m × 5 m = 50 W → choose a 24 V, ≥65 W driver. Try our Power Supply Calculator.

Wiring & placement tips

- Injection spacing (rough): 24V every 5–10 m; 12V every 2.5–5 m. Inject more often for higher W/m or thin wires.

- Tail length matters: plan where the power supply (PWS) will be mounted and choose tail lengths so the heavy‑current tails are short. Longer tails = more drop.

- For long runs, feed both ends or split into segments with injection points. Use aluminium profiles for heat.

Not sure what tail length or driver size you need? Use the calculator or contact our team.

Need help choosing a product? Contact our team with your room size, strip model, and total run length.